Vaiya Clothing Factory Bangladesh – Leading Apparel & Garment Manufacturer & Supplier

Bangladesh stands as the world’s second-largest exporter in the readymade garments (RMG) and textile industry, delivering premium apparel manufacturing solutions through knitwear and woven garments production.

Our export-oriented industry serves global brands through comprehensive OEM, private label, and CMT services from strategically located facilities across Dhaka, Chittagong, and key industrial zones.

As certified members of BGMEA and BKMEA, we operate and partner with compliance factories that meet international standards while offering competitive wholesale clothing from Bangladesh solutions.

Our garment factory in Bangladesh specializes in full-package production, combining traditional craftsmanship with modern technology to serve Bangladesh clothing manufacturers seeking reliable, scalable partnerships.

Why Bangladesh is the World's Garment Manufacturing Hub

Bangladesh has emerged as a dominant force in the global apparel supply chain, contributing over $40 billion annually to international markets through its robust RMG sector.

The country’s textile industry benefits from strategic trade agreements, including GSP and EU GSP+ preferences, attracting significant foreign direct investment (FDI) from leading international buyers such as H&M, Zara, Walmart, and Primark. The Bangladesh Garment Manufacturers and Exporters Association (BGMEA) represents over 4,500 factories, while the Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA) oversees the knitwear sector’s exponential growth.

This organized structure ensures consistent export performance and maintains strong buyer-supplier relationships across the global apparel supply chain.

Key advantages include:

- Competitive labor costs with skilled workforce.

Established infrastructure supporting large-scale production. - Government incentives for export-oriented industries.

Strategic location providing easy access to global markets. - Comprehensive support from BGMEA and BKMEA associations.

Our Product Range & Manufacturing Capabilities Knitwear vs. Woven Garments

Our facilities specialize in both knitwear and woven garments, offering complete flexibility for diverse product requirements. Knitwear production includes stretch fabrics ideal for casual wear, while woven garments provide structured solutions for formal and workwear applications.

Apparel Categories:

T-shirt Manufacturing

Basic tees, premium cotton, organic options.

Polo shirt production

Pique, jersey, performance fabrics

Hoodie manufacturer

Fleece, cotton blends, custom designs

Sweater manufacturing

Knitted pullovers, cardigans, seasonal collections

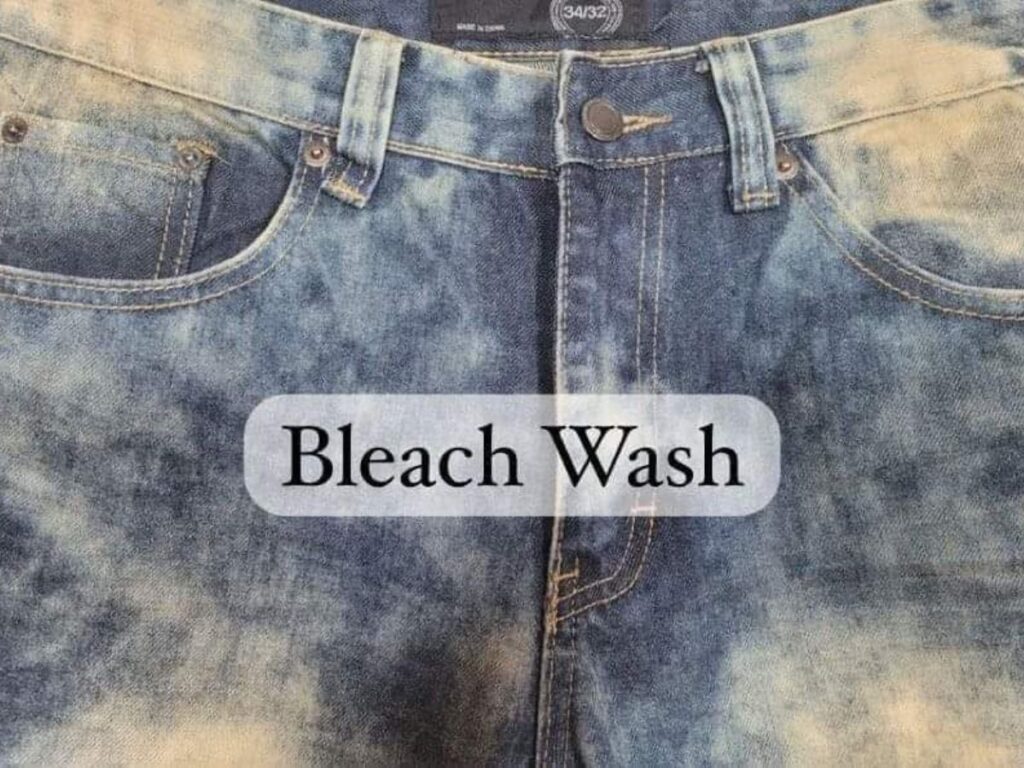

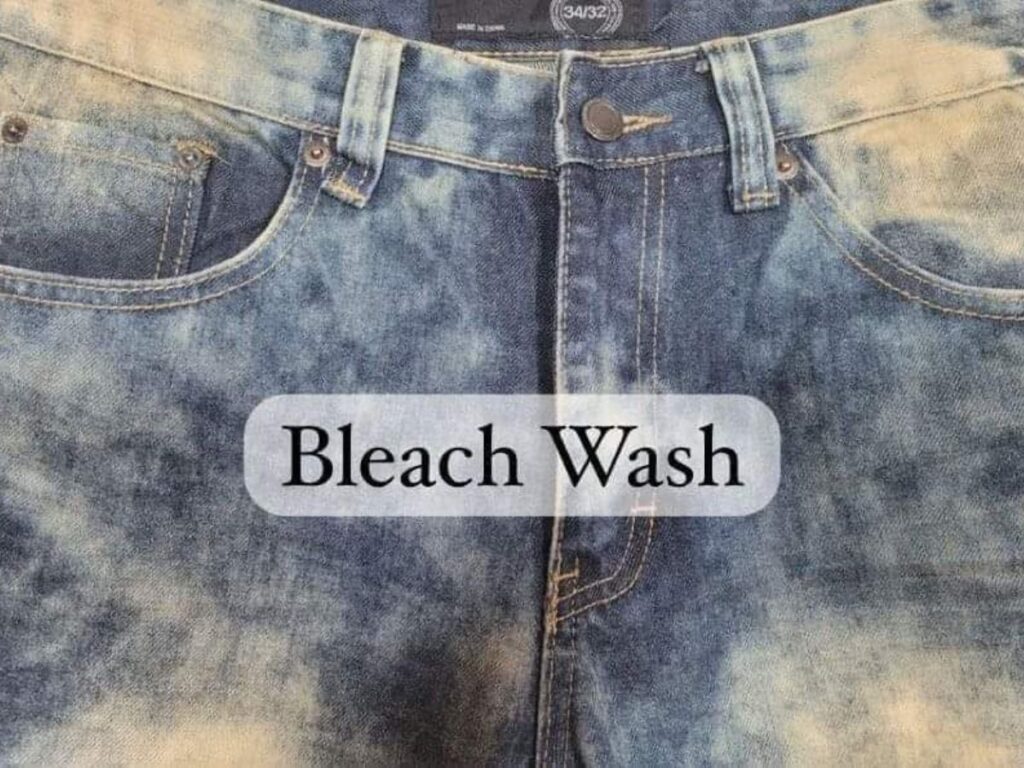

Denim jeans

Classic cuts, stretch denim, sustainable options

Jacket manufacturing

Windbreakers, blazers, technical outerwear

Uniform manufacturing

Corporate, industrial, healthcare uniforms

Sportswear

Athletic wear, activewear, performance fabrics

Children's clothing

Age-appropriate designs, safety-compliant materials

Headwear

Caps, hats, hijabs, scarves, headbands

Underwear production

Basics, performance, organic cotton

Leggings

Yoga pants, athletic leggings, fashion styles

Workwear

Safety-compliant, durable construction

Raincoats

Waterproof, breathable, seasonal protection

Towels

Bath, beach, gym towels in various weights

Manufacturing Services

Private label clothing

Custom branding, packaging, design

OEM production

Specification-based manufacturing

CMT services

Cut, make, trim operations

Full package production

Design to delivery solutions

Sample development

Prototyping, fit sessions, approval samples

Bulk order production

Scalable manufacturing for large orders

Factory Locations

Our strategic presence across Bangladesh’s key industrial zones ensures optimal production efficiency and logistics coordination:

Dhaka: The capital serves as our primary garment hub, housing administrative offices and flagship production facilities. This location provides access to the largest skilled workforce and comprehensive support services.

Chittagong: Our port city manufacturing facilities leverage direct access to international shipping routes, reducing lead times and logistics costs for export-oriented production.

Narayanganj: Specialized knitwear production center, historically known as the “Dundee of Bangladesh” for its textile heritage and concentrated expertise in knitted garments.

Gazipur: Modern industrial zone featuring state-of-the-art facilities with advanced machinery and compliance infrastructure.

Ashulia & Savar: Emerging industrial areas with purpose-built garment factories designed for efficiency and worker welfare.

Bangladesh Export Processing Zones (BEPZA): Our BEPZA facilities benefit from streamlined export procedures, duty-free imports, and enhanced infrastructure supporting international trade.

The Bangladesh garment factories approach ensures:

- Reduced production costs through economies of scale.

- Shared infrastructure and logistics networks.

- Access to specialized suppliers and service providers.

- Enhanced quality control through industry best practices.

Compliance, Certifications & Social Responsibility

Fire Safety & Social Compliance

Our partnered and compliance factory operations adhere to the highest international standards, ensuring safe working conditions and ethical manufacturing practices. We maintain certifications from leading global organizations:

Key Certifications:

- WRAP (Worldwide Responsible Accredited Production): Comprehensive social compliance.

- BSCI (Business Social Compliance Initiative): European standard for ethical trade.

- OEKO-TEX Standard 100: Textile safety and environmental criteria.

- ISO 9001: Quality management systems.

- SEDEX: Supplier ethical data exchange platform.

- LEED Certification: Green building and environmental standards.

Safety & Compliance Measures:

- Accord on Fire and Building Safety: Structural and fire safety compliance.

- Alliance for Bangladesh Worker Safety: Comprehensive safety programs.

- Regular social compliance audits by international third parties.

- Fire safety compliance with automated systems and emergency protocols.

- Labor rights protection, including freedom of association.

- Minimum wage compliance exceeds national standards.

- Worker welfare programs include healthcare and education.

Sustainability Certification

Our commitment to sustainable garment factory operations includes:

- Environmental management systems.

- Water treatment and recycling programs.

- Energy efficiency initiatives.

- Waste reduction and recycling protocols.

- Chemical management and safety programs.

Manufacturing Process: From Fabric Sourcing to Export

Our comprehensive clothing manufacturing process ensures quality and efficiency from initial concept to final delivery:

Pre-Production Phase:

- Fabric sourcing: Premium materials from certified suppliers.

- Yarn dyeing: Color matching and quality control.

- Pattern making: Technical design and grading.

- Sample room: Prototype development and approval.

Production Phase:

- Bulk production: Scalable manufacturing systems.

- Quality control (QC): Multi-stage inspection processes.

- Inspection: Final quality verification.

- Garment finishing: Pressing, packaging, labeling.

Export Phase:

- Packing and shipping: Secure packaging and logistics coordination.

- Export documentation: Comprehensive paperwork and compliance.

- Logistics: International shipping and delivery tracking.

Key Process Elements:

- Lead time: Optimized scheduling for timely delivery.

- Minimum Order Quantity (MOQ): Flexible requirements based on product complexity.

- FOB (Free on Board): Competitive pricing structure.

- CIF (Cost, Insurance, Freight): Comprehensive shipping solutions.

Order placement: Streamlined communication and tracking systems.

For Buyers: OEM, Private Label, CMT & Bulk Orders

Order Types:

- OEM (Original Equipment Manufacturer): Manufacturing to buyer specifications

- Private label: Custom branding and packaging solutions

- CMT (Cut, Make, Trim): Basic manufacturing services

- Full package: Complete design-to-delivery solutions

Sample Development Process:

- Initial design consultation and specification review

- Sample room prototype creation

- Fit sessions and design refinements

- Approval samples and final specifications

- Production planning and scheduling

Minimum Order Quantities:

- T-shirts and basics: 1,000 pieces per style/color

- Complex garments: 500 pieces per style/color

- Private label: Negotiable based on customization level

Bulk orders: Preferred quantities 5,000+ pieces

Price Negotiation & Order Placement

Pricing Structure:

- Competitive FOB pricing from Bangladesh ports

- Volume discounts for large orders

- Seasonal pricing adjustments

- Price negotiation based on long-term partnerships

Order Process:

- Inquiry and specification submission

- Quotation and price negotiation

- Sample approval and production planning

- Order placement with confirmed specifications

- Production monitoring and quality control

Shipping and delivery coordination

Sustainability & Green Manufacturing - Eco-Friendly Initiatives

Our sustainable garment factory operations prioritize environmental responsibility and social impact:

Environmental Programs:

- Green factory certification and operations

- Wastewater treatment plants with advanced filtration

- Energy efficiency through renewable sources and LED lighting

- Recycling initiatives for fabric waste and packaging materials

- Chemical management and reduction programs

Carbon footprint monitoring and reduction

About Us: BGMEA, BKMEA, BEPZA, BTMA & International Buyers

As proud members of Bangladesh’s leading industry associations, we maintain the highest standards of professionalism and compliance:

Memberships & Affiliations:

- BGMEA (Bangladesh Garment Manufacturers and Exporters Association): Full member status

- BKMEA (Bangladesh Knitwear Manufacturers and Exporters Association): Active participation

- BEPZA (Bangladesh Export Processing Zone Authority): Authorized manufacturer

- BTMA (Bangladesh Textile Mills Association): Industry collaboration

International Buyers:

Our established relationships with global brands include partnerships with major retailers and fashion companies across North America, Europe, and Asia. We serve international buyers through dedicated account management and customized service solutions.

Regulatory Compliance:

- Compliance auditing firms: Regular third-party assessments

- Labor unions: Collaborative worker representation

- Government regulatory compliance and reporting

International trade agreement adherence

Worker Welfare & Community Impact

Social Responsibility:

- Women’s employment programs supporting gender equality

- Skill development, training and career advancement

- Healthcare and education support for workers and families

- Fair trade practices and transparent supply chains

- Community development projects and local partnerships

- Worker welfare committees and grievance mechanisms

Labor Standards:

- Minimum wage compliance and regular reviews

- Labor rights protection and union recognition

- Safe working conditions and regular safety training

Work-life balance initiatives and flexible scheduling

(FAQ) MOQ, Lead Time, Certifications, Order Process, Working Conditions

Let’s Make It Happen!

Ready to work with a fresh, dependable T-shirt manufacturer? Let’s talk about how we can meet your casual apparel needs. Reach out now:

Business: Vaiya Clothing Factory Bangladesh – T Shirt Manufacturer in Bangladesh & Garments Factory in Bangladesh

Address: 1230, Dhaka, Bangladesh

Phone: +8801340773541

Drop your details in our quick contact form below, and let’s get your casual T-shirt production started. Vaiya Group is ready to manufacture—let’s do this!